Copyright © Jiangsu Sinyoda Environmental Equipment Manufacturing Co., Ltd. All Rights Reserved. Site Map

- +86-15366806173

- yd15366806173@qq.com

- No. 45 Longhu Road, Jintan District, Changzhou City, Jiangsu Province

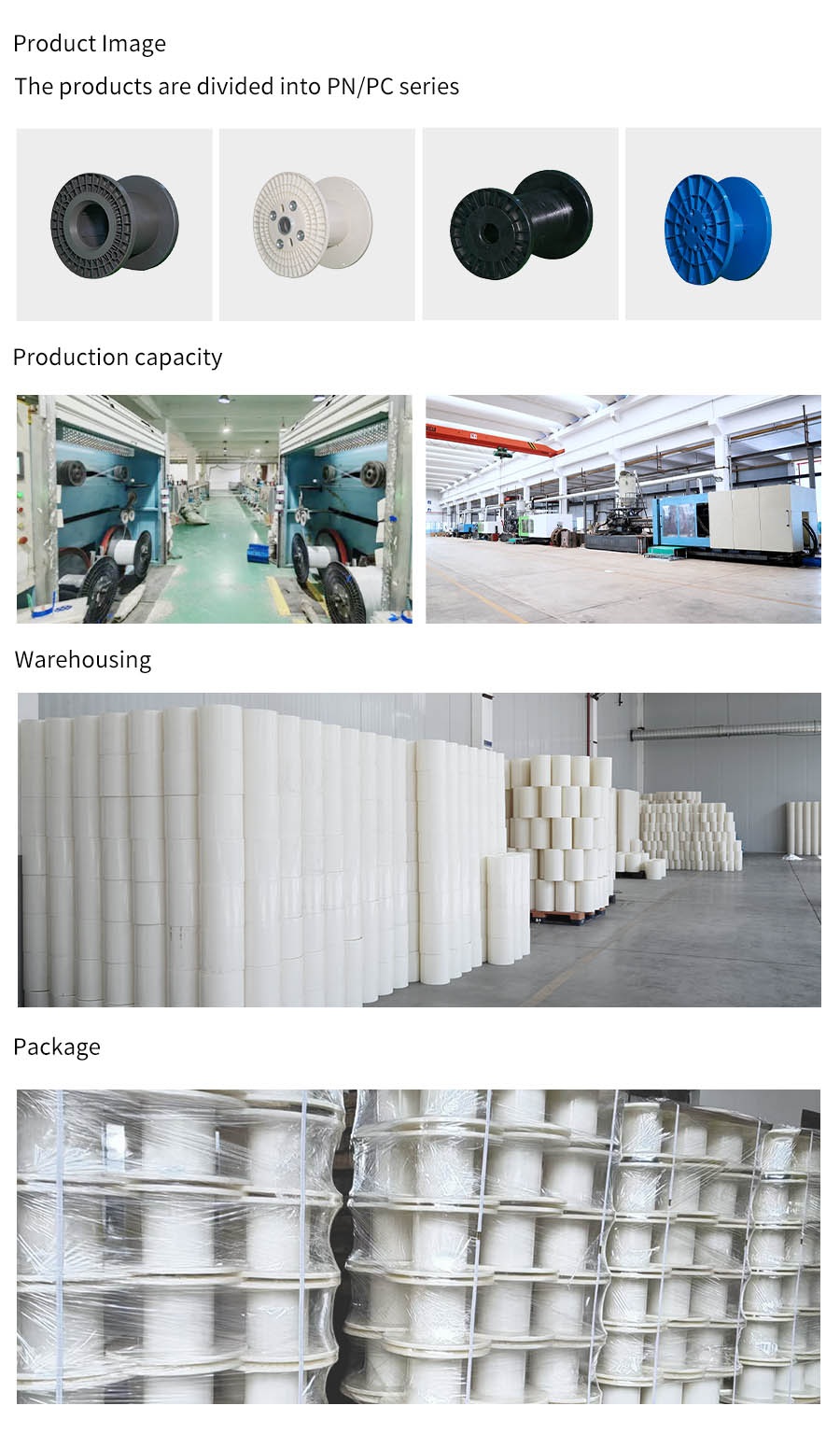

3. Plastic reels (plastic hollow shafts) for optical fiber and cable manufacturers can be customized to meet specific dimensional, product (reel weight), and dynamic balancing requirements. Service process: (Customer consultation and demand matching) - (Determination of demand type) - (Standard products: Confirm model and quantity to provide quotation and contract; Customized products: Technical solution matching, provide drawings and quotation) - (Contract signing and advance payment) - (Production and processing) - (Customer confirmation) - (Balance payment) - (Logistics delivery) - (Customer acceptance) - (Long-term after-sales service support)

Serial number | Model | Side plate diameter | Cylinder diameter | Shaft hole diameter | External width | Inner width | Side panel thickness | Execution hole radius | Execution hole center distance | Standard disk |

1 | PN200A | 200 | 90 | 25 | 118 | 95 | / | / | / |

|

2 | PN200B | 200 | 90 | 25 | 178 | 155 | / | / | / |

|

3 | PN265A | 265 | 90 | 26 | 188 | 155 | / | / | / |

|

4 | PN265B | 265 | 130 | 26 | 185 | 155 | / | / | / |

|

5 | PN300A | 300 | 130 | 36 | 230 | 200 | 15 | 10 | 50 |

|

6 | PN300B | 300 | 160 | 45 | 300 | 270 | 15 | 8 | 60 |

|

7 | PN315A | 315 | 130 | 36 | 236 | 200 | 12 | 10 | 50 |

|

8 | PN315B | 315 | 160 | 36 | 190 | 160 | 12 | 10 | 50 |

|

9 | PN350 | 350 | 160 | 45 | 300 | 270 | 12 | 8 | 60 |

|

10 | PN400A | 400 | 200 | 56 | 310 | 270 | 16 | 11 | 61/73 | Enhanced |

11 | PN400S | 400 | 200 | 56 | 300 | 250 | 20 | 11 | 61/73 | Enhanced |

12 | PN400C | 400 | 200 | 56 | 300 | 265 | 16 | 11 | 61/73 |

|

13 | PN400D | 400 | 200 | 56 | 155 | 120 | 16 | 11 | 61/73 |

|

14 | PN400E | 400 | 200 | 56 | 315 | 265 | 16 | 11 | 61/73 |

|

15 | PN500A | 500 | 250 | 56 | 300 | 250 | 20 | 12 | 70/100 | 6 screws |

16 | PN500S | 500 | 250 | 56 | 300 | 250 | 25 | 12 | 70/100 | Enhanced |

17 | PN500C | 500 | 250 | 56 | 375 | 315 | 20 | 12 | 70/100 | 6 screws |

18 | PN500D | 500 | 250 | 56 | 450 | 400 | 20 | 12 | 70/100 | 6 screws |

19 | PN500D | 500 | 250 | 56 | 450 | 400 | 20 | 12 | 70/100 | 4 screws |

20 | PN630A | 630 | 250 | 56 | 375 | 315 | 25 | 12 | 61/95 | 4 screws |

21 | PN630B | 630 | 250 | 56 | 450 | 400 | 25 | 13 | 34/67 | 4 screws |

22 | PN630C | 630 | 315 | 56 | 375 | 315 | 25 | 13.5 | 69/112 | 6 screws |

23 | PN630C | 630 | 315 | 56 | 475 | 400 | 25 | 13.5 | 69/112 | 6 screws |

24 | PN800A | 800 | 315 | 80 | 600 | 500 | 35 | 15 | 99/124 | 6 screws |

25 | PN800B | 800 | 400 | 80 | 600 | 500 | 35 | 20 | 110/160 | 12 screws |

26 | PN800C | 800 | 400 | 127 | 600 | 500 | 35 | 20 | 110/160 | 12 screws |

27 | PN1000A | 1000 | 500 | 80 | 750 | 625 | 35 | 21 | 116/157 | 3 screws |

28 | PN1000B | 1000 | 500 | 127 | 750 | 625 | 35 | 21 | 116/157 | 3 screws |

29 | PN1050A | 1050 | 500 | 80 | 925 | 800 | 40 | 21 | 113/156 | 12 screws |

30 | PN1050B | 1050 | 500 | 100 | 880 | 800 | 40 | 21 | 113/156 | 12 screws |

31 | PN1050C | 1050 | 500 | 100 | 925 | 800 | 40 | 21 | 113/156 | 12 screws |

32 | PN1050D | 1050 | 500 | 80 | 925 | 800 | 40 | 21 | 113/156 | 12 screws |

Serial Number | Model | Side plate diameter | Cylinder diameter | Inner width | Outer width | Shaft hole diameter | Side plate thickness | Material | Structure |

1 | PC66 | 66 | 35 | 75 | 85 | 30 | 5 | ABS / nylon | One |

2 | PC80 | 80 | 22 | 80 | 100 | 10 | 10 | ABS / nylon | One |

3 | PC84 | 84 | 34 | 50 | 58 | 17 | 2.5 | ABS | One |

4 | PC90 | 90 | 32 | 70 | 80 | 20 | 10 | ABS | One |

5 | PC100 | 100 | 50 | 76 | 90 | 22 | 2.5 | ABS | Assembly |

6 | PC122 | 122 | 32 | 76 | 80 | 22 | 2.5 | ABS | Assembly |

7 | PC125 | 125 | 64 | 100 | 120 | 30 | 10 | ABS/PP/PS | One |

8 | PC128 | 128 | 80 | 100 | 120 | 25 | 10.5 | ABS/PP/PS | One |

9 | PC185 | 185 | 130 | 1600 | 180 | 25 | 10.5 | ABS/PP/PS | One |

10 | PC200A | 200 | 90 | 93 | 114 | 155 | 10.5 | ABS/PP/PS | Glued |

11 | PC200B | 200 | 90 | 155 | 178 | 100 | 10.5 | ABS/PP/PS | Glued |

12 | PC202 | 202 | 152 | 95 | 106 | 24 | 3 | ABS/PS | Glued |

13 | PC220 | 220 | 120 | 85 | 95 | 25 | 5 | ABS/PS | Glued |

14 | PC230 | 230 | 106 | 190/255 | 200/265 | 100 | 5 | ABS/PS/PP | One |

15 | PC250 | 250 | 125 | 200 | 240 | 45 | 20 | ABS/PS | Glued |

16 | PC250 | 250 | 125 | 330 | 290 | 45 | 20 | ABS/PS | One |

17 | PC261 | 261 | 106 | 160 | 200 | 22/45.2 | 7.5 | PP / New materials | One |

18 | PC262 | 262 | 110 | 231 | 246 | 106 | 20 | PP / New materials | One |

19 | PC275 | 275 | 165 | 320 | 350 | 30 | 15 | PP/PE | Glued |

20 | PC300 | 300 | 110 | 130 | 160 | 38/40/45 | 15 | ABS | One |

21 | PC300 | 300 | 170 | 170 | 200 | 30 | 15 | ABS | Assembly |

22 | PC315 | 315 | 130 | 200 | 230 | 44 | 15 | ABS/PP | Glued |

23 | PC370 | 370 | 150 | 282 | 45 | 68 | 16 | ABS/PP | Assembly |

24 | PC400 | 400 | 150 | 290 | 56 | 20 | 20 | ABS | Assembly |

25 | PC400 | 400 | 150 | 290 | 56 | 20 | 20 | ABS | Assembly |

26 | PC400 | 400 | 200 | 250 | 68 | 20 | 20 | ABS | Assembly |

27 | PC400 | 400 | 250 | 250 | 26 | 68 | 20 | ABS | Assembly |

28 | PC500 | 500 | 250 | 355 | 28 | 68 | 20 | ABS | Assembly |

29 | PC500 | 500 | 250 | 290 | 26 | 68 | 20 | ABS | Assembly |

30 | PC500 | 500 | 250 | 315 | 250 | 68 | 20 | ABS | Assembly |